- Home

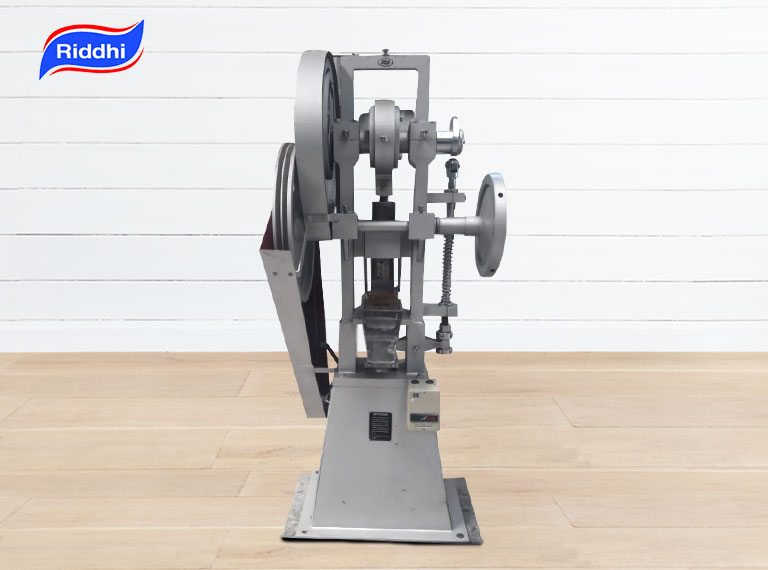

- Single Punch Tablet Press

The single punch tablet press, also known as the eccentric press or single station press, is the most basic tablet production machine. As the name indicates, a single punch tablet utilizes a single set of station tooling consisting of a die and a pair of upper and lower punches. Our offered Single Punch Tablet Press is a small yet powerful solution that is excellent for pharmacies, hospitals, and academic, pharmaceutical, and nutraceutical laboratories.

Gives you better results.

Our High Quality Product

This tough machine, with an interior main body cut from a single piece of steel, can create 2-50 mm-sized tablets, offering unrivaled levels of stability, accuracy, and lifespan.

It enables pharmacies and start-ups to produce tablets in small batches directly. We are a distinguished Single Punch Tablet Press suppliers in Maharashtra. Our concept is based on customer happiness, and we provide machines of the greatest quality. Its compression mechanism is made of nickel-plated steel or SS, and it is separated into three pieces.

SINGLE STROKE HEAVY DUTY TABLET PRESS MACHINE – 80MM

The top unit houses the upper punch, which compresses the powder in the loading chamber, while the below component contrasts the compression and extraction of the punched tablet. Anticorodal anodized aluminum is used to make the feeder and other fittings.

| SALIENT FEATURES |

| Robust & Compact Design |

| Easy & Simple Operation |

| No skilled labour is required |

| APPLICATION |

| This machine is used for Pharmaceutical and Veterinary Products |

| Maximum size of tablet |

|

| Maximum depth of fill | 50 mm |

| Diameter of die | 75 mm |

| Depth of die | 40 mm |

| Max. Stroke pressure | 12 TO 15 Tons |

| No. of Strokes per min. | 30 TO 35 |

| Electric Motor | 2 H.P. / 440 V/50 CYLS/Phase/ 960 RPM |

| Lubrication | Oiling and greasing nipples provided at Various points. Also available with Central Lubrication System at an additional cost. |

| Diameter of Plunger | 60 mm |

| Feed of Powders | Gravitational |

| Stand | Fabricated |

| Body | Fabricated |

| Feed Frame | Chrome Plated Gun Metal |

| Hopper | 7 Kgs. Capacity Stainless Steel 304 Grade. Also available in Stainless Steel 316 Grade. |

| Dies | Made of HCHC/OHNS/EN38 Steel . One set of Dies Comprises of one upper punch, one lower Punch and one die. |

| Overall Dimensions | 2 Ft (L) X 2.5 Ft (B) X 5 Ft (H) Approx. |

| Weight | 350 Kgs. Approx. |

SINGLE STROKE LIGHT DUTY TABLET PRESS MACHINE – 50 MM

The top punch exerts compaction force on the fill material while the bottom punch remains static, this action is akin to hammering motion, and as a result, the single punch press is referred to as the stamping process. Its external touch-screen display allows for real-time monitoring of production data and parameters such as production speed, compression data, single punch test mode, automatic production mode, and alerts.

| SALIENT FEATURES |

| Robust & Compact Design |

| Easy & Simple Operation |

| No skilled labour is required |

| APPLICATION |

| This machine is used for Pharmaceutical and Veterinary Products |

| Maximum size of tablet | 50 mm |

| Maximum depth of fill | 30 mm |

| Diameter of die | 75 mm |

| Depth of die | 40 mm |

| Max. Stroke pressure | 12 TO 15 Tons |

| No. of Strokes per min. | 30 TO 35 |

| Electric Motor | 2 H.P. / 440 V/50 CYLS/Phase/ 960 RPM |

| Lubrication |

|

| Diameter of Plunger | 60 mm |

| Feed of Powders | Gravitational |

| Stand | Fabricated |

| Body | Fabricated |

| Feed Frame | Chrome Plated Gun Metal |

| Hopper | 7 Kgs. Capacity Stainless Steel 304 Grade. Also available in Stainless Steel 316 Grade. |

| Dies | Made of HCHC/OHNS/EN38 Steel . One set of Dies Comprises of one upper punch, one lower Punch and one die. |

| Overall Dimensions | 2 Ft (L) X 2.5 Ft (B) X 5 Ft (H) Approx. |

| Weight | 350 Kgs. Approx. |

Modifications to fit the needs of the clients!

Our press can generate 60-85 tablets per minute. It is also possible to operate it by hand. On this press, just one pair of punching dies can be installed. Both the filling depth of the substance and the thickness of the tablet are changeable. It is designed with high precision of filling, low noise, low material consumption, and smooth operation.

Request A Quote

Quick Contacts

Please feel free to contact our friendly staff with any medical enquiry.

- Mob. No.: +91-9821018579/9969994187

- Location: Om shivam, Gr. Floor, 2, Tarun Bharat, Sahar Road, Andheri East, Mumbai -400099, India

- Mail: sales@riddhipharma.com